CNC Machining Capacities

Feature | Description |

Maximum Part Size | Milled parts up to 80” x 24” x 30”. Lathe parts up to 62” length and 18” diameter. |

General Tolerances | Tolerances on metals will be held to +/- 0.005" unless otherwise specified. |

| Precision Tolerances | ACAL can manufacture and inspect to tight tolerances per your drawing specifications including GD&T callouts. |

| Minimum Hole Size | 0.015”. This may vary depending on part geometry and chosen material. |

| Threads and Tapped Holes | ACAL can accommodate any standard thread size. We can also machine custom threads; these will require a manual quote review. |

| Surface Finish | The standard finish is as-machined: 125 Ra or better. Additional finishing options can be specified when getting a quote. |

Machining Equipment

Lathe

- Mazak Quick Turn QT20 CNC

- Mazak Quick 18N Universal CNC

- Mazak Quick Turn Universal 350

- Hardinge Super Precision DSM-59

- Mazak Nexus 100

- Haas ST-35LY CNC Turning Center (with live tooling)

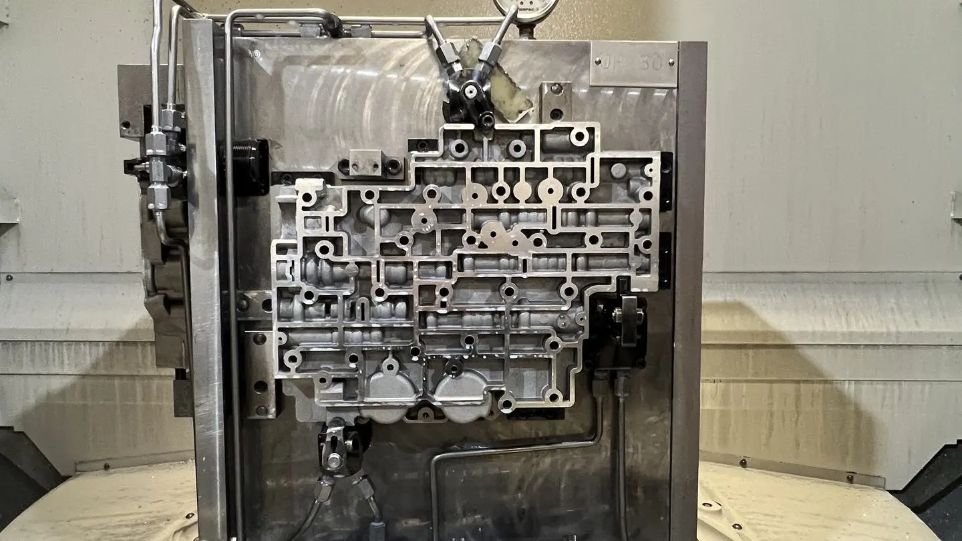

Mill

Vertical

- Mazak VTC-300C

- Bridgeport w/2 Axis Digital Readout

- Bridgeport w/Prototrak 2 Axis CNC

- Hurco VM1 VME1 CNC (with 4th Axis)

- Hurco VMX42 (with 4th Axis)

- Hurco VMX50i (with 4th Axis)

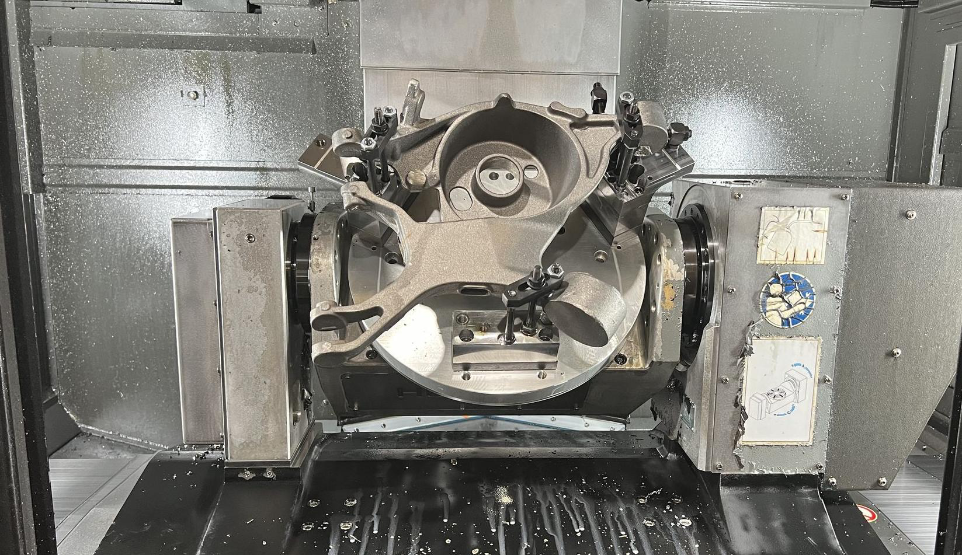

Horizontal

- Makino A71NX

- Mazak Horizontal 5000II

- Mazak Horizontal 6000E

- Mazak Horizontal 6800

- Hurco Vertical HXT500

5-Axis

- Hurco VMX30Ui